Product

- screen baskets

- What is screen basket?

- Filter

- Wedge wire filtration system

- Surface treatment

- Wire machining(Electrical discharge machining)

- Welding & Machining

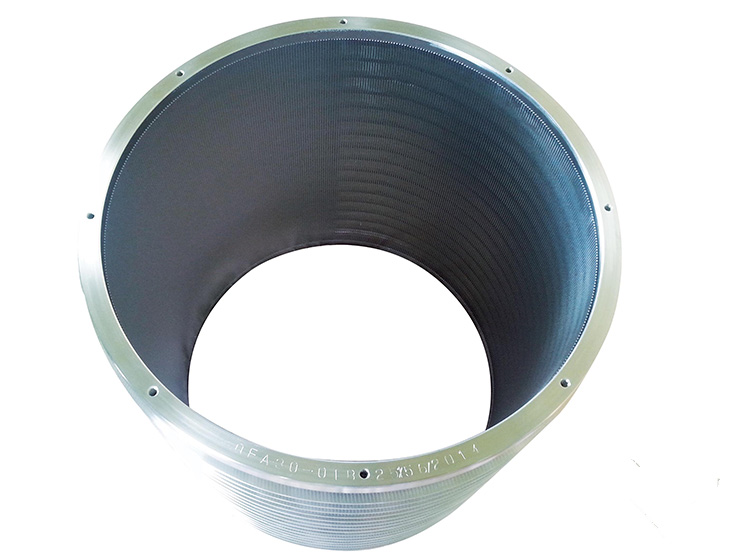

screen baskets

Most important choice for production of paper.

Improvement of quality of paper, elevation of productivity, and lowering production cost are decided by Screen basket. Screen basket of Garam guarantees to bring tour company the best quality and productivity, and satisfactory outcome in lowering productions cost.

Wedgewire designed with superior technology makes effective eliminnation of foregin substances and production of stronger screen basket, and supply more open areas.

We've approached scientifically to screening and separating of fiber, and made the utility maximized.

In addition, with the superior technology with surface treatment, we're adding the nice look to the screen basket, and make the life of the screen basket much longer.

Screen basket of Garam guarantees progressive Lowering Production Cost, Elevation of Productivity, Improvement of quality for your company.

Garam's wire is selected optionally considering the length of fiber, dissociation or separation, type of paper, Productivity, efficency on elimination of foreign substance, and durability of Screen Basket.

The choice of appropriate screen baskets is extremely important in the pulp and paper industry.

They can improve paper quality, elevate productivity and lower production costs, LASER KEYED screen baskets manufactured by GARAM SCREEN provide guaranteed quality and productivity.

Wedge wire bar type construction when designed and manufactured with superior technology effectively eliminates foreign substances and gives more open area and higher throughput and results in a stronger screen.

These factors have been maximized by GARAM SCREEN.

In addition with our high technology surface treatment, we have increased screen life and surface smoothness.

Screen basket by GARAM guarantee lower production costs, raise productivity and improve the quality of your products.

GARAM's wire is carefully chosen for length of fiber, screening or fractionation, type of paper, efficiency of elimination of foreign substances, durability and productivity of the screen basket.

What is the screen basket?

There is a process to separate, dissociate and screen fibroid materials screen (filter) used in this process is called as a screen basket, net, filter or screen cylinder.

In other words, paper finally comes out after the process of making, continuously spreading and ironing the soft paper gruel, and the screen basket is used for this paper gruel.

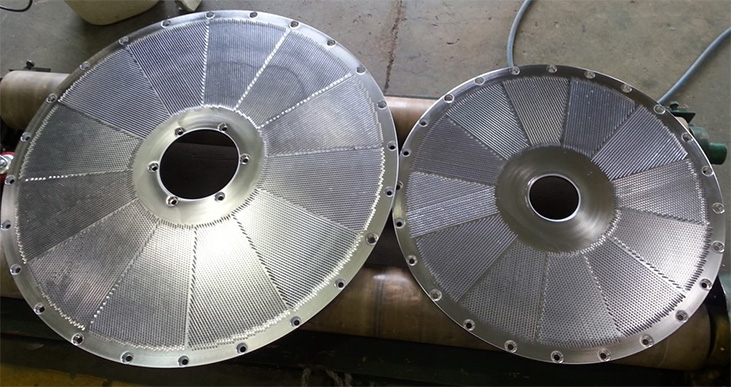

Filter

It is a processing technology of metal boards for a coffin, which was not possible done by the existing operations of metal punching, corrosion, and drilling.

It is applicable to various companies (ex: Oil chemical products, non-organic/organic chemicals, fertilizers, pharmaceutical, foods, metal engineering, plastics, etc.)

that require domestic centrifugal separator companies and filtering filters by processing stainless and metal boards for a coffin of materials below 1t with 0.2-0.5mm of hole and slot form(pitch about 1mm).

Futhermore, it is far more inexpensive than razor processing and has superior quality such as non-occurrence of both sides chip and also be able to produce 40 of forms which cannot be made by razor process.

In addition, it is a product that has realized a substantial improvement in its inner composition and appearance by electrolytic polishing special hard plating, etc when used as a metal filter, and thus, it has already gained favors from domestic centrifugal separator companies.

We are even expecting the effect of replacing imports and retro-exports with this product.

Also, it is a new technology with domestic patent, which can substantially contribute to cost reduction.

Wedge wire filtration systems

Since the triangular wires are regularly welded to the rods maintaining equal slot openings, this wedge wire screen experiences no clogging or laxation Compared with the current wire mesh method or perforated pipe method, this wedge wire screen method maximizes durability by keeping equal slots and by maintaining maximum slot open area resulting in high efficiency and as well as applying spot welding to each point where wires and rods meet.And they are also designed to be easily installed, 304, 316L materials are used for standard screens, However, we also use other materials for special screens Wedge wire screens are widely used in various fields such as petrochemical industry, water treatment system, starch, food industry, mining, paper making and pulp, etc.

Surface treatment

Electrolytic polishing

Surface roughness

Remove foreign material

Pure cupper plating

Transport of superconductor

The largest facility in the nation

Chromium plating

Extension of lifetime

Smooth surface

Wear resistance

Adjust HRC by 45~46

Enlargement/reduction of slot width

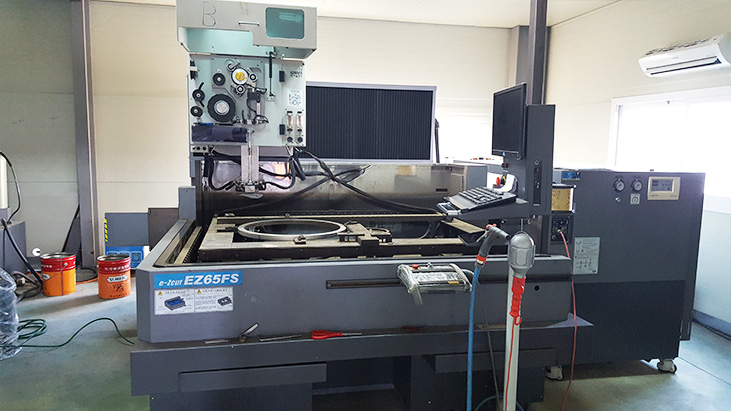

Wire machining

Ultraprecision machining (Tolerance 1/70000)

Welding & Machining

Arc welding

Plasma welding : Range (0.5A ~ 500A)

Laser welding